Looking for a world record?

If that’s what you expect, you’re in the right place.

Before Maxflow delivers the best results to customers, he does the following.

It makes the cylinder head from our customers as clean as possible and purifies them from their rust.

Then the internationally valid Superflow Flowbench tester initially measures CFM for each millimeter lift value.

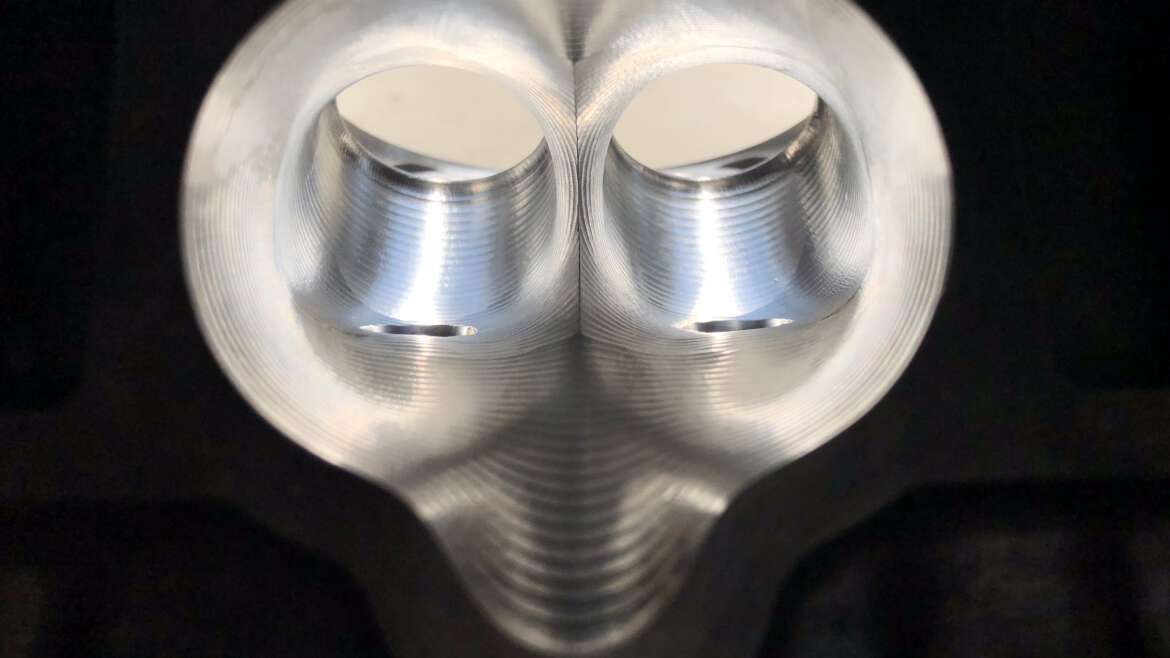

If the cover to be processed is to be processed for the first time in the maxflow, the 3-D shape is created in digital media by scanning the ports of the Rottler CNC cover.

Then, looking at the code that the cover has, the shaft shaft is machined to see the limits of the cover on another identical cover.

As a result, safe limits are determined on the original port and different designs are created within these limits.

These designs are designed specifically for the construction and shape of the cylinder head using the principles of fluidic mechanics.

These designs are processed individually in CNC, taking measurements in flowbench.

The most efficient result is determined and the final version of the design is determined.

This design with the best results is processed on our customers’ cylinder heads in our CNC.

Because we think that CNC Porting is the best and the same for every port, but that’s how we can be sure, and the tests and research that we do prove it.

The CNC is also repurged and polishing the machined cover to its ports.

The CFM measurements of the final cover are then taken.

From the results before and after, a report is prepared by writing the test conditions.

The CNC port cover is packaged by the thermoform method.

It is then placed in a wooden or plastic case and is filled with Styrofoam.

The test results are placed on and the cover of the chassis is closed.

Now it’s ready to add a horse to your vehicle.